Shanghai Precise

CIP, Clean In Place Machine, Simple Maintenance 1000L/H

CIP, Clean In Place Machine, Simple Maintenance 1000L/H

Automatic CIP system, Clean in Place

CIP system is one of necessary cleaning equipments to clean the pipes and containers in dairy industry beverage, and pharmacy, and acts as a key in ensuring the quality of the goods.

The Automatic CIP (Clean in Place) system comprises alkali tanks, acid tanks, hot water tanks, clear water tanks, backwater tanks, disinfecting water tanks, concentrated acid tanks, concentrated alkali tanks, heat exchangers, CIP processing pumps, as well as relevant pipes, valves, and an electric control system. These tanks can be allocated based on the specific technological requirements of customers. In most cases, the cleaning needs can be fulfilled with just three tanks: alkali tanks, acid tanks, and hot water tanks.

Our company offers various types of CIP systems, including:

-

Manual CIP cleaning central station: This system allows manual control of cleaning period, cleaning temperature, acid and alkali concentration, and valve switches.

-

Semi-automatic CIP cleaning central station: In this system, the cleaning period, acid and alkali concentration, and valve switches are manually controlled. However, the cleaning temperature can be automatically adjusted by regulating the steam flow.

-

Full-automatic CIP cleaning central station: This system enables automatic control of the cleaning period, cleaning temperature, acid and alkali concentration, and valve switches.

For heating, the CIP cleaning stations can employ four modes: plate type heater, tubular heater, coil type heater, and steam straight-through heating. The design can incorporate one loop up to eight loops or more, depending on the specific technological requirements of customers.

Our CIP cleaning systems offer a comprehensive solution for effective and efficient cleaning in place, catering to a wide range of industries and applications.

Collections

-

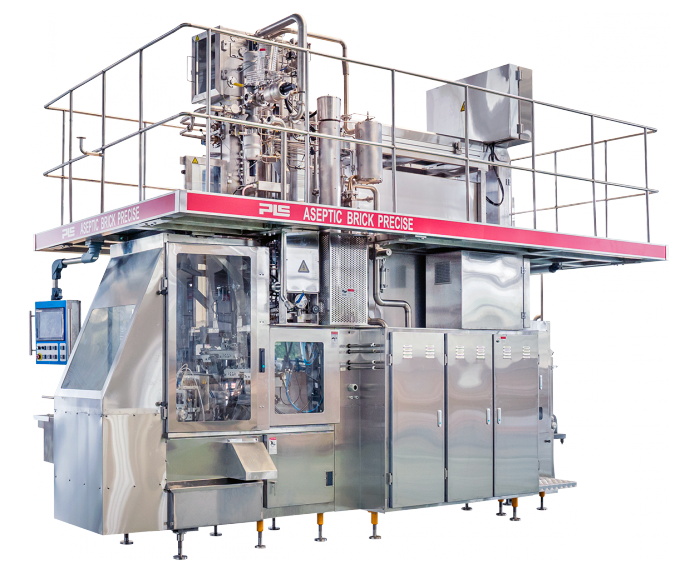

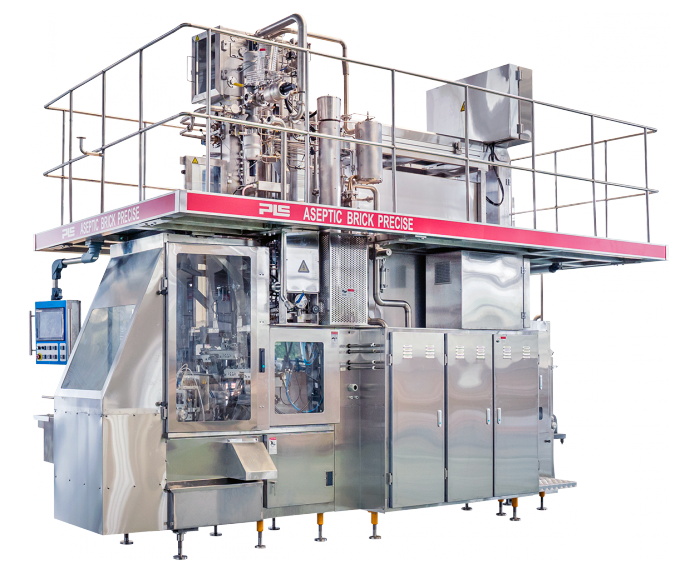

Aseptic filling machine

With a comprehensive range of filling machines, we can ensure the efficient...

-

Homogenizer

HIgh Pressure Juice And Milk Homogenizer MachineThe mixed medium go into and...

-

Sterilisation machine

Commercially sterile food needs to be heated to specific temperatures for prescribed...